![]()

Silicone Strength

Innovative structural glazing sealants provide sticky solution for advanced façade designs

By William Davis, Senior Engineer, Technical Services, Vitro Architectural Glass & Florian Doebbel, Business Development Manager, Vertical Glass, Sika Corporation

Pick an adjective—sophisticated, elaborate, innovative or just plain big—to describe today’s high-rises, and it would be spot-on. Form is definitely in, as contemporary building façades reap the benefits of innovative architectural designs that incorporate expansive lites of glass, advanced energy-saving technologies and elegant curtain walls

Functionality is equally important, with glass specifications increasingly requiring energy-efficient products to comply with the more-stringent environmental regulations and meet sustainability objectives. Apart from  that, complex details require compatibility of materials, a design appropriate for the material used, a structural performance in favor of an optimized use of materials and a reliable durability of the entire system or unit.

that, complex details require compatibility of materials, a design appropriate for the material used, a structural performance in favor of an optimized use of materials and a reliable durability of the entire system or unit.

These impressive structures are no longer outliers; they are the norm, each with its own “personality” that brings prestige to cityscapes and notoriety to the corporations whose logos are emblazoned on their façades.

A common feature to many of these new building is their sleek exterior appearance, which is often the result of structural silicone glazing (SSG), a technique growing in popularity, in which a silicone adhesive bonds glass and other panel materials such as metal directly to the structure.

One of the most versatile forms of curtain wall construction in commercial façades, SSG technology has expanded the architectural “playbook,” leading to a new wave of buildings with strikingly dramatic façades that are not only aesthetically appealing but also structurally sound.

A Mature Industry

Structural glazing systems, in their most basic form, are curtain wall systems consisting of glass—either monolithic, laminated, dual-glazed or triple-glazed insulating glass units (IGUs)—that is bonded or anchored directly to a structure without the use of glazing gaskets, anti-walk blocks, glazing channels, thermal breaks, exterior covers and other components.

The unique appearance and simplicity of construction that structural glazing offers often cannot be achieved with other glazing methods. In addition, this type of construction can improve many of the performance characteristics of the system or building. In this construction, a structural silicone sealant adheres the glass or metal panels to supporting framing members. The incorporation of a structural silicone sealant into the system gives architects a new level of design freedom, eliminating the need for exterior retainers and covers. As a result, it is now easier to design buildings with a completely flush appearance, very clean architectural lines and smoother rain runoff, which allows glass facades to shed dirt and become easier to clean.

Structural glazing can be incorporated into many systems, including curtain walls, storefronts, and other applications that use conventional captured glazing. The rules that apply to the structural design of conventional framing systems also apply to structurally glazed framing systems. Analysis of building dynamics, such as building sway, wind load and seismic movements, is required to determine what loads are applied to the silicone and glass or metal framing, and to ensure that movements can be accommodated without damage.

How it Began

The emergence of SSG technology in the mid-1960s spawned a proliferation of smooth, uninterrupted, high-performance façades, reflecting architects’ newfound freedom to pursue “push the envelope” designs. The early glass-to-glass structural seals, developed by PPG (now Vitro Architectural Glass), evolved into a two-sided application in 1970 in which silicone sealants adhered two sides to metal framing members, with the head and sill of the glazing captured into a glazing channel with compression glazing. A year later, the industry ushered in the debut of four-sided applications that utilized silicone sealants solely to attach glass to metal mullions.

Today’s robust SSG market is fueled by the growing demand for advanced façade systems in the commercial building and construction sector, along with the need for more environmentally friendly and energy-efficient structures that can withstand a variety of conditions. This demand, combined with the increasing number of extreme weather events, prompted the need for more advanced sealants and adhesives.

The Use of Silicone in IGUs

As building façades began to evolve through the use of innovative glass products, IGUs were used in two-sided applications in the mid-1970s; then in four-sided applications by the end of the decade. The use of IGUs demonstrated the versatility of silicone sealants. Not only did these sealants hold the glazing to the side of a building façade; they also were the structural component holding the lites of glass together in the construction of the IGUs themselves.

Contemporary curtain wall construction must be able to withstand a unique combination of environmental pressures. Sealant joints must be resistant to UV exposure and environmental pollutants such as acid rain; function effectively under daily thermal movements and wind loads; and withstand seasonal thermal cycles, extreme winds and seismic events. These conditions require high-performance silicone sealants and adhesives that are specially formulated and tested to meet the demanding performance requirements of contemporary curtain wall technology.

When structural silicone sealant is used to adhere the glass to the supporting framing members, the glass is cushioned and adhered in place to reduce the possibility of glass edges impacting framework. In hurricanes, heavy winds can generate high loads and a pumping effect upon the windows. The use of structural silicone sealant allows the glass to be retained with evenly distributed elastic support.

In a standard one-inch IGU, the primary seal consists of polyisobutylene, which acts as the main barrier against moisture vapor transfer and inert gas loss.

Structural silicone forms the secondary seal; this seal holds the lites of glass together. In addition, the silicone helps transfer applied loads, protects the primary seal (which never cures) and prevents the IGU spacer from being displaced or moving into the vision area.

This silicone adhesive provides excellent resistance to UV light and weathering, and its mechanical properties remain unchanged during wide temperature fluctuations.

Advantages of Silicone Sealants

Sealant technology, analytical techniques and computing technology have significantly advanced over the history of structural glazing without much change to the design method. Sealant technology has progressed with neutral curing formulations, increased tensile strengths and higher movement capability.

In an SSG system, the silicone sealant seals the building from the elements and supports the curtain wall, transmitting wind loads and other impact loads from the glass to the structure. Properly designed and installed structural silicone performs well in the presence of UV exposure, adverse weathering conditions and extremely harsh environments. It can withstand conditions such as flexure, tension, compression, thermal shear stresses and continuous movement. These qualities allow structural silicone sealants to remain the only type of sealant approved for structurally adhered glazing applications, according to AAMA.

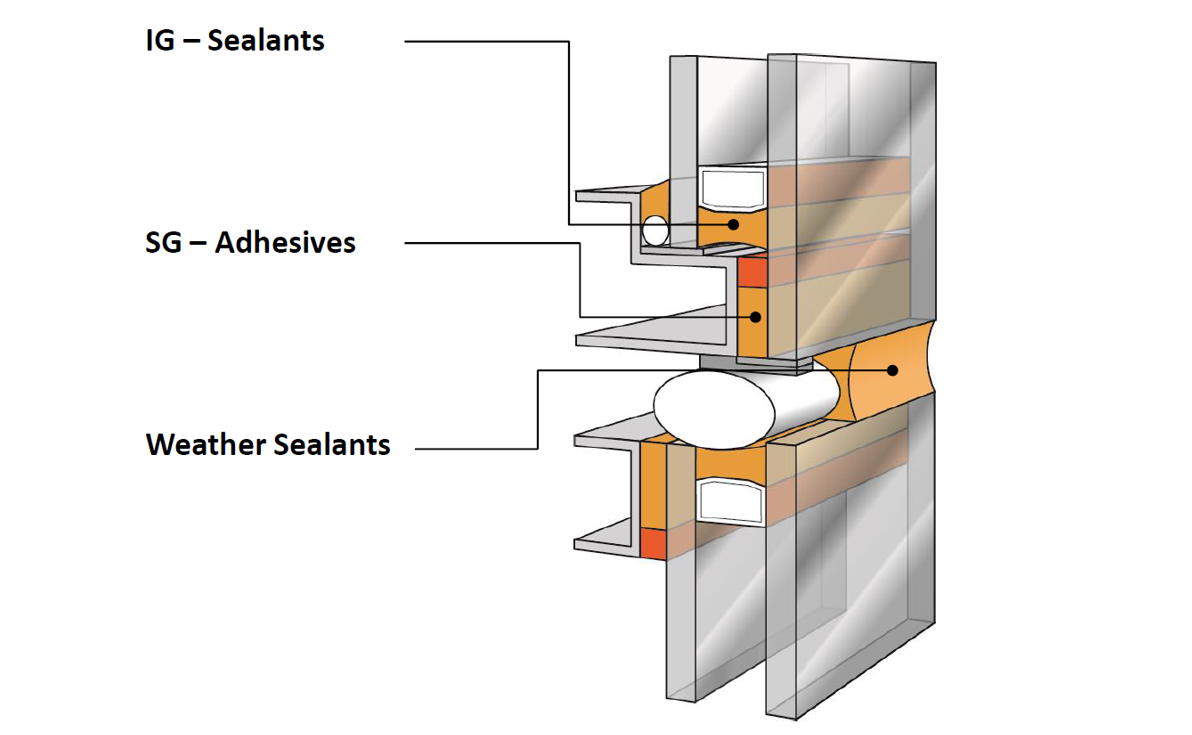

In a typical structural silicone application, the following materials may be used:

- Insulating glass sealant tested according to ASTM C1184 or ASTM C1369 and to be used with an allowable design strength of 20 PSI. This sealant can be applied in a factory setting.

- Structural glazing adhesive test according to ASTM C1184 and to be used with an allowable design strength of 20 PSI. This sealant can be field-applied, or if a unitized curtain wall, will be factory-applied, with the entire unit hung against the building.

- Weather sealant classified according to ASTM C920 and to be used with an allowable movement accommodation capability between ±35% and ±50%. This seals the interface between the lites of glass or the two unitized curtain walls and must be compatible with both the structural glazing components and the IGU’s edge sealing system.

High-Modulus Silicones

Unlike standard silicone adhesives, high-modulus silicones are stiffer, enabling them to better retain the argon (insulating) gas in an IGU. This enhanced retention is the result of the silicone’s ability to limit the movement of the glass panes caused by climatic changes (extreme cold and heat). In addition, high-modulus silicones prevent over-pressing of the primary seal as a result of “pillowing” out or squeezing back in of the hermetically sealed glass lites. The stabilizing effect of a high-modulus secondary seal is also relevant for IG units assembled with soft-spacer systems, which provide only a limited resistance for the edge sealing system compared to rigid metal or plastic spacers.

As a result, the glass will be held together more tightly, the primary seal will be more durable, and IGUs will have a longer service life.

Structural glazing applications using a high-modulus silicone can produce three significant benefits:

- The strength of the high-modulus silicone requires less product to construct the IGU. This benefit can be even better utilized for the entire system by fixing the IG units with high-strength structural glazing adhesives to the carrier frame.

- The bond, or contact, width can be narrower, and if slimmer aluminum frames can be used, then less aluminum overall will be needed, resulting in substantial cost savings.

- Finally, the optimized use of materials helps to reduce system-embodied energy and the carbon footprint of manufactured products.

Secondary Seal Industry Standards

When constructing IGUs for applications with commodity-type silicone products, the following ASTM standards must be met:

- Structural silicones that passed either ASTM C1184 or ASTM C1369.

- The allowable design strength for dynamic tensile loading must be limited to 20 psi acc. to ASTM C1401 and ASTM C1249.

- The shear in dead-load unsupported units must be limited to 1 psi. This refers to the weight of the glass itself hanging on the structural silicone joint without any effective support of setting blocks or other mechanical devices.

Other essentials of verifying structural silicone joints for its specific use are the calculation approach and the level of simplification as well as the knowledge of all relevant load impacts. For IG units, considerations must include climatic load effects and the load-sharing level between the inner and outer lites of glass.

Stretching the Value of Silicone: Hudson Yards

Numerous variables affect the stability of IGUs—and, in turn, the overall strength and long-term durability of those units—in structural silicone glazing applications. Although ASTM accounts for these factors in establishing industry standards to improve the design of IG units (ASTM C1249 and ASTM E1300), Professor Dr. Franz Feldmeier, Rosenheim University of Applied Sciences, added new variables to those standards to determine the impact on glass and the silicone holding the IGU together. Those variables include items such as the shape and dimensions (or aspect ratio) of the IGU, the direction of the relevant loading and environmental conditions (not just the correct ratio of the glass according to the glass thickness).

Although the ASTM calculations have provided a baseline for acceptable performance since 1971 (the year of America’s first multi-story structural silicone glazing project), Feldmeier’s enhanced calculations came into play during the construction of the Hudson Yards complex in New York. That is where they helped the project designers and engineers for a specific building to more accurately assess the demands on all the components in the highly loaded IG units that were fabricated for a complex unitized curtain wall design.

For two transom designs, ASTM calculations based on the standard criteria determined the need for extensive bites of silicone for the structural secondary seal, but they did not take into account the accurate boundary conditions and the existing system capacity. That was followed by a series of refinements and more precise Feldmeier calculations, which produced results much closer to the practical conditions the secondary seals would face, and helped engineers to optimize the edge sealing dimensions, as shown below.

Window Conditions

- Standard Unit Size: 59.1" x 161.4"

- Bigger Unit Size: 104.3" x 177.2"

- Glass Configuration: 3/8" x ½" x 5/16"

- Four-sided structurally bonded

- Inner lite additionally bonded to one or two intermediate transoms

Wind Loading

Up to -5.8kPa (-121psf)

Isochoric Pressure

16.6kPa (347psf)

Using Feldmeier’s expanded calculations, the calculated load impact on the secondary seal decreased by 34 percent. Sika Corp., a leading supplier of sealants, adhesives and other specialty chemical products and industrial materials, conducted a finite element analysis (FEA) involving computer modeling, accounting for the added structural silicone bond between inner glass and the intermediate transoms. This analysis demonstrated that there was increased stiffness and reduced load-transfer to the outer glass and the secondary seal, which resulted in an 81 percent reduction in deflection.

The effect of Feldmeier’s calculations and the introduction of high-modulus silicone produced dramatic savings in bond-line width, as seen in the following table.

|

Calculation Method/ |

Transom Design #1 Required Secondary Seal Bite |

Transom Design #2 Required Secondary Seal Bite |

|

Standard ASTM/Standard Sealant |

32 mm |

39 mm |

|

Feldmeier/Standard Sealant |

21 mm |

26 mm |

|

Feldmeier/High-Modulus Silicone |

16 mm |

19 mm |

|

FEA/High-Modulus Silicone |

12 mm |

9 mm |

Conventional ASTM procedures were created to provide simplified design requirements and to cover most basic standard configurations while delivering results and recommendations on the safe side. These procedures are not designed to account for the real interaction of all system components or the specific performance of any type of customized structural silicone. Feldmeier’s expanded calculations do account for these variables, and thereby expand the range of options available to optimize the edge-seal without compromising safety or durability.

The extra effort required to make more detailed calculations is always beneficial if the simplified standard approach requires silicone bites larger than those that are normally used, as the potential for additional silicone volume can impact cost, production processes and even the overall feasibility of a project. Larger silicone bites require more material and slow down the productivity of the sealer and the IG line.

The maximum silicone bite is limited by the capacity of the automated sealer, the application quality, and even by the curing process of the silicone itself. Any two-part silicone will release by-products while curing. The deeper the silicone bite, the longer the release and chemical curing of the silicone will take. Silicone bites larger than 30 millimeters should not be produced without consulting the equipment supplier and silicone producer.

Providing a design that is more efficient for the weakest unit in a project helps to optimize appearance and cost for all units in a project. The engineering of IG units, including the secondary seal products and dimensions, is mandatory for all designs and applications different from basic standard designs and loading. In many cases, this engineering enables more efficient use of the material. In other situations, it helps to improve the understanding of impacts on all parts of an IG unit, which helps to increase safety and durability.

Three Steps to an Expanded Vision Area

Applying this philosophy to the Hudson Yards project referenced earlier, a standardized ASTM calculation indicated the need for large secondary seal silicone bites (32 and 39 millimeters, respectively) on the two transom designs and, in this specific case, an incredibly high safety margin. This threatened to undermine the feasibility of the transom design and would have precluded the efficient use of materials and production capacity.

Using the more-advanced calculation approach based on the Feldmeier concept, the required bond line width of the secondary seal bite for the two transom designs was reduced to 21 millimeters and 26 millimeters, respectively. This enabled production with an automated IG sealer, which ensured the ability to meet strict quality requirements while guaranteeing an appropriate curing progress for the completed silicone bites.

Adding a higher performing silica with the Feldmeier concept reduced the bond line width requirements for secondary seal bites even further: to 16 and 19 millimeters, respectively. This significantly reduced silicone consumption and further increasing the productivity of the IG line.

The final calculation—which incorporated FEA computer modeling with the higher-performing silicone and the Feldmeier concept—shrunk the bond-line width requirements for the secondary seal bites to 12 mm and 9 mm, respectively, which was well under the acceptable threshold. This final step moved the edge-seal completely out of vision area and helped to meet the design demands of the building owner and the architect.

Conclusion

Thousands of buildings around the world have been constructed with aesthetically slender curtain frame profiles using structural silicone glazing. As a result, the technology has a well-earned reputation increasing reliability along with enhanced visual and functional value for IGUs.

Along the way, silicone sealant manufacturers have introduced products with enhanced chemistries to meet the needs of increasingly sophisticated curtain wall and façade designs.

The evolution of the technology, highlighted by higher-strength silicones for bonding and laminating, to meet the needs of a growing variety of applications while withstanding adverse conditions such as earthquakes, UV, acid rain, wind, seasonal temperature fluctuations and impact loads, signals a robust market for this type of glazing.

Testing methods and standards have also progressed, further reinforcing the long-term advantages of this approach, and setting the stage for potentially even more advances in the future.

William Davis is a technical services senior engineer at Vitro Architectural Glass (formerly PPG Flat Glass). In this position since 2017, he supports the company’s Intercept® stainless steel spacer system technology. Davis holds a Bachelor of Science degree in mechanical engineering from Point Park University in Pittsburgh.

Florian Doebbel is Business Development Manager for Sika Corporation located in Lakewood, NJ. He has 15 years of experience in the industry, including engineering and consulting positions at Sika Corporation (USA), Sika Services AG (Switzerland) and Glas Statik Konstruktion GmbH (Germany). He has been a key resource for advanced design of building façade elements and is highly skilled in the area of structural glass and silicone. Florian is a Graduate of Technical University Dresden, Structural Engineering.